Capabilities & Services

C-130

SERIES AIRCRAFT ENHANCEMENTS AND MODIFICATIONS

As the world has come to realize the Lockheed C-130

is the major aircraft type that can operate

worldwide in any weather or physical conditions.

Snow Aviation LLC International (SAI) has prepared their

C-130 series of standard and optional modifications

to allow the aircraft to fly safely and meet the

conditions being demanded by the circumstances

facing their operators worldwide today. Many

potential customers cannot afford the cost of new

versions of the C-130J aircraft series which are

running well in excess of $97 million each to solve

the requirement to replace wing components that are

running out of time, old avionics, electrical

equipment, mission systems updates, etc. on the

older C-130 models. Removal of this older C-130

installed equipment is being demanded as the safety

upgrades on these older aircraft by the countries

that are experiencing tremendous flight increases on

their flight control agencies and the added mission

requirements to meet the potential customers

military operational demands of today. The C-130

Series of Aircraft need to be able to fly at slower

speeds and work with requirements based on minimum

developed runways, mountainous terrain and other

demanding situations that the current terrorist’s

look for their training and continuing operations

areas to penetrate a country. Many of these SAI

modifications listed herein have been successfully

demonstrated to the US Government during a series of

demonstration contracts flown by SAI under military

contracts from 2005 to 2007. The following listings

describe the proposed C-130 modifications SAI

intends to offer for the 850+ C-130B/E/H Series

aircraft not being serviced by Lockheed today, but

still needed by these older aircraft in over 70

countries worldwide today. Not all of these SAI

offerings will be bought by every potential

customer, however, over 450 of these customers are

considered as being prime for selecting most of the

items listed below as their C-130s are still the

aircraft relied upon to perform the required

operations against the current terrorist and

insurgent situations and natural disasters being

demanded of them worldwide

As the world has come to realize the Lockheed C-130

is the major aircraft type that can operate

worldwide in any weather or physical conditions.

Snow Aviation LLC International (SAI) has prepared their

C-130 series of standard and optional modifications

to allow the aircraft to fly safely and meet the

conditions being demanded by the circumstances

facing their operators worldwide today. Many

potential customers cannot afford the cost of new

versions of the C-130J aircraft series which are

running well in excess of $97 million each to solve

the requirement to replace wing components that are

running out of time, old avionics, electrical

equipment, mission systems updates, etc. on the

older C-130 models. Removal of this older C-130

installed equipment is being demanded as the safety

upgrades on these older aircraft by the countries

that are experiencing tremendous flight increases on

their flight control agencies and the added mission

requirements to meet the potential customers

military operational demands of today. The C-130

Series of Aircraft need to be able to fly at slower

speeds and work with requirements based on minimum

developed runways, mountainous terrain and other

demanding situations that the current terrorist’s

look for their training and continuing operations

areas to penetrate a country. Many of these SAI

modifications listed herein have been successfully

demonstrated to the US Government during a series of

demonstration contracts flown by SAI under military

contracts from 2005 to 2007. The following listings

describe the proposed C-130 modifications SAI

intends to offer for the 850+ C-130B/E/H Series

aircraft not being serviced by Lockheed today, but

still needed by these older aircraft in over 70

countries worldwide today. Not all of these SAI

offerings will be bought by every potential

customer, however, over 450 of these customers are

considered as being prime for selecting most of the

items listed below as their C-130s are still the

aircraft relied upon to perform the required

operations against the current terrorist and

insurgent situations and natural disasters being

demanded of them worldwide

SAI Installation of an Auxiliary

Power Unit (APU) and Removal of the Older C-130 GTC/ATM

Components

The current Gas Turbine Compressor (GTC)

installation in the earlier C-130/L-100 aircraft

supplies the compressed bleed air to power the AIR

Turbine Motor (ATM) which in turn powers the DC

electrical generator in the upper fuselage portion

of the center wing which supplies electrical power

while the aircraft is on the ground without the

aircraft’s engines running.

SAI Dual Battery Installation

SAI has developed and flown a dual battery

installation for the C-130 that meets the current US

Federal Aviation Administration (FAA) and US

Military Electrical Power/Emergency Service Time

Requirements in case of a complete power generation

failure on an aircraft

SAI Electrical Control and

Distribution System

SAI has also designed, produced, ground and flight

tested a new electrical control and distribution

system that has also been issued a US FAA

Supplemental Type Certificate (STC) for this new

system on a C-130/L-100. In addition, the USAF has

issued a Technical Order (TO) 704E that requires all

of their aircraft to meet the provisions for proper

power levels and power stability for the new

aircraft and support system requirements for retro

equipment still in use on the older aircraft.

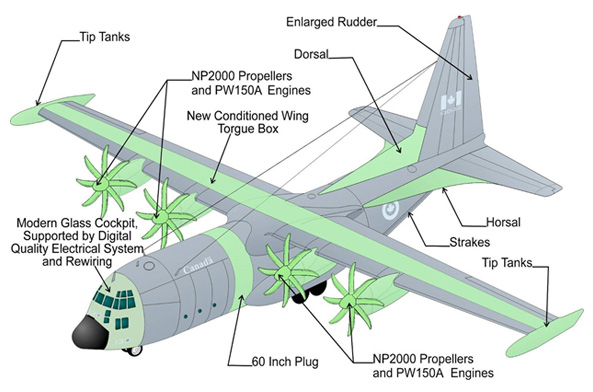

ABS Dorsal Fin HF Antenna Mount

Installation

This installation removes the two long line HF

antenna wires from the front top of the aircraft

thus reducing the aerodynamic drag on the aircraft

by approximately 3% while improving the HF

transmission and reception capabilities and

significantly lowering of the associated system

maintenance requirements.

SAI Enlarged Dorsal Fin

The SAI enlarged dorsal fin was designed, built and

installed by SAI and then flight tested under

contract with the USAF on our prototype C-130E.

SAI Enlarged Rudder

The SAI enlarged rudder was designed, built and

installed by SAI and then flight tested under

contract with the USAF on our prototype C-130E.

SAI Wing Tip Fuel Tanks and Associated Outer Wing

AND Fuel System Modifications

The new SAI Wing Tip Fuel Tanks installation were

designed, built and installed by SAI and then flight

tested under contract with the USAF on the SAI

C-130E prototype aircraft.

SAI Aft Fuselage Strakes

SAI Aft Fuselage Strakes

SAI also has designed a set of C-130 Aft Fuselage

Strakes that they will build and flight test with

installation on their demonstration aircraft. Aft

fuselage strakes have previously been installed on a

C-130 fuselage and they did reduce aft fuselage drag

and provide a contribution to the airframe’s

stability at slow airspeeds.

UTC Carbon Brakes and Lock Ring

Wheels

The UTC carbon brakes, and lock ring wheels allow a

minimum of 8 times as many braking operations as the

current multiple steel disk brakes before they need

to be changed. The lock ring wheels allow a tire

change in 28 minutes versus 23 hours for a similar

tire change on a standard C-130/L-100 tire and wheel

installation.

SAI Glass Cockpit Modification

Installation

SAI has improved its original glass cockpit over the

last 17 years since we installed it in our company’s

C-130A Testbed Aircraft.

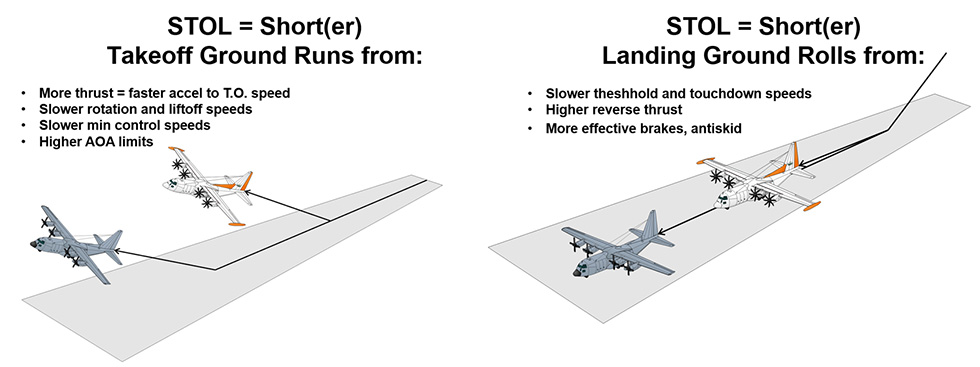

Engine Upgrades

SAI can accomplish engine upgrades for replacement

of the earlier T56-A-7A/B series engines with the

more powerful T56-A-15 or LFE version of the T56-A

Series engines. The T56-A-15 series engines offer

Shorter Airfield Take-off and Landing and faster

climb and cruise airspeed capabilities for the

earlier C-130B/E Models.

RR-Allison Engine Upgrades to the

T56-A-15, Series 3.5 Standard

SAI believes that the T56-A-15, Series 3.5 is the

most efficient means for the early C-130B/E/H

operators to gain additional power, capability and

reliability for their aircraft to meet their growing

market demands. SAI believes that the installation

of the T56-A-15, Series 3.5 on the older C-130 plus

installation of the appropriate SAI Modification

Programs for their missions will give these

operators the best return of economy and reliable

productivity they can have from their C-130s.

SAI Nacelle and Associated Nacelle

Structures

SAI has designed and analyzed new forward and aft

engine nacelle components to reduce the stress

concentrations between the current engine mount and

the front spar of the wing. SAI’s analysis shows a

loads concentration reduction of approximately 50%

for this mounting area utilizing the new SAI engine

mounts, QEC and aft engine nacelle designs.

Hamilton Sundstrand 8 Bladed

NP2000 Composite Propellers and Electronic Propeller

Control

SAI was the first company to install the Hamilton

Sundstrand NP2000 8 bladed composite propellers on

its C-130E test aircraft in 2006. The NP2000

propellers increased the thrust at the start of the

takeoff roll by 28% while still producing 12%

increase in thrust at aircraft lift off during

takeoff.

SAI install C-130H Nose Gear and

Installation Package

The C-130H component and mounting structure can be

overhauled, tested and installed in 30 days. The SAI

nose gear installation of the C-130H Nose Gear

Mounting Structure and Nose Gear Component is

superior or earlier variants.

New Cockpit Seats

The seats are smaller, lighter and much more

comfortable than the traditional C-130 cockpit

seats. The seats have over 30 adjustments and

provide a very comfortable and functional seating

arrangement. The seats mount in the traditional

cockpit seat rails and allow much more free space in

the immediate area of the cockpit seats than with

the standard C-130 cockpit seats.

C-130 Airframe Overhaul

Because of the amount of update and modification

work being accomplished on this aircraft it makes an

overhaul of the airframe a very economical operation

if accomplished along with the other referenced work

being accomplished.

Electrical Cockpit Air

Conditioning

SAI designed the installation kit and installed the

original smaller Electrical Cockpit Air Conditioning

unit from their selected sub-contract manufacturer

in our prototype demonstration C-130A aircraft and

it cooled our cockpit on a 104-degree day at Eglin

AFB to 70 degrees and kept it there while the

aircraft was on the ground and the unit running on

power from a ground aircraft power unit. This

air-conditioning unit is electrically powered and

can be run from a ground power unit or the

aircraft’s electrical system while airborne.

SAI Newly Developed Cargo Handling

System

SAI has designed and engineered a new cargo handling

system for the C-130 and L-100 series of sircraft.

The system features fold down outer locking system

rails that can be rapidly folded down or moved up to

provide maximum width for loading wheeled equipment

or placed up to horizontally and vertically

stabilize the outboard portions of

pallets/containers.

A New Sub-Cargo Floor Mounting

Winch System

SAI is aware of the standard times it takes with the

older C-130s for an aircrew to unload and reload

their aircraft with different types of loads while

supporting their military missions in the field.

Positioning a winch and attached cables on top of

the cargo floor to be moved by the loading crew

assists the loading of a heavy load which is tiring

and time consuming with a 300-pound winch.

Aircraft Cockpit Galley

Aircraft Cockpit Galley

Aircraft galleys with the plan to upgrade the C-130

cockpit of the older C-130 series aircraft with a

new galley utilizing new solid state and state of

the art components. The proposed unit will be

lighter, require considerably less power, operate at

temperatures on the outside of the galley components

installation that are cooler than the current C-130

galley units, have more capacity and require

significantly less maintenance.

SAI Horsals

SAI has designed, will build and test the new aft

fuselage horsals for the C-130 as soon as a customer

requests them, or a decision is made by SAI to

include them on their demonstration aircraft.

SAI’s C-130E/H – L-100 Fuselage

Stretch

The C-130 and L-100 fuselage stretch engineering was

initiated by the commercial L-100 operators to

increase their cargo cubic payloads.

C-130 Lightning Protection System

SAI has designed a new lightning dissipation system

for the C-130. The system concentrates on lightning

hits on the nose, wing tips and vertical fin areas

of the aircraft.

SAI Trailing Arm Nose and Main

Landing Gear

SAI originally designed its trailing arm landing

gear components for its SA-200 series aircraft

design which was subsequently modified to withstand

the added physical loads associated with the

heaviest C-130s currently in use or as demonstrated

by the SAI prototype aircraft to the USAF under

contract.

C-130 Wing Work

A real concern for many of the older C-130 operators

is the total time on their aircraft’s center wings.

If the center wing is out of time or approaching

major restrictions on its operation the time to

address the problem is when SAI is doing all the

work described in a proposal. SAI only replaces

center wings with the heavy weight USAF center wing

components or a rebuild of the center wing to the

same heavy weight specifications.